Success Through Saving – Refurbished Vending Machine

The refurbished vending machine process can help you save money. No matter how long you’ve been in vending, common sense tells you that spending less money is a sure way to be more successful. At A&M Equipment Sales, we couldn’t agree more. That’s why we developed the most comprehensive refurbishment process in the industry. Our process takes a machine from “as is” status to “like new,” providing trouble-free service for a fraction of the cost of a new machine.

Because we have decades of vending operator experience, we fully understand the wants and needs of vending operators, their staffs and their customers. But don’t take our word for it; you be the judge.

THE A&M “LIKE NEW“ REFURB PROCESS

At A&M Vending Machine Sales we acquire vending machines either by trade or purchase from all across the United States.

We assess each vending machine’s condition. Determining which machines meet our high standards for refurbishment. The remaining vending machines that do not pass our refurbishing requirements are used for parts, sold as is, and in some cases recycled.

When a vending machine meets our refurbishment requirement it is ready to begin its refurbishing journey. All working components such as delivery bins, product shelves, coin changers, bill validators, credit card readers, computer boards, and digital displays are removed. What remains is a bare cabinet.

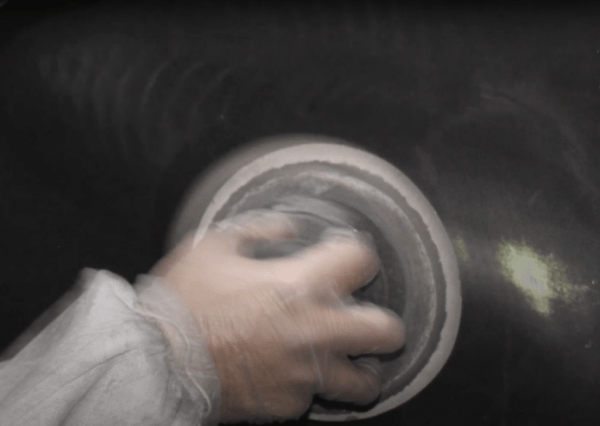

The vending machine now moves on to our body work department. Here the cabinet is cleaned and prepped for painting. It is at this point any major dings or dents are repaired and the entire cabinet is sanded.

The prepped vending machine cabinet is now moved to our OSHA and EPA compliant paint booth. Protecting our employees and the environment is a top priority with the A&M Refurbishing Process. The entire cabinet is painted to professional automative standards.

Once painting is complete the vending machine cabinet moves to our drying room. Here it will stand for 24 hours before any work begins. This allows for complete curing of the paint.

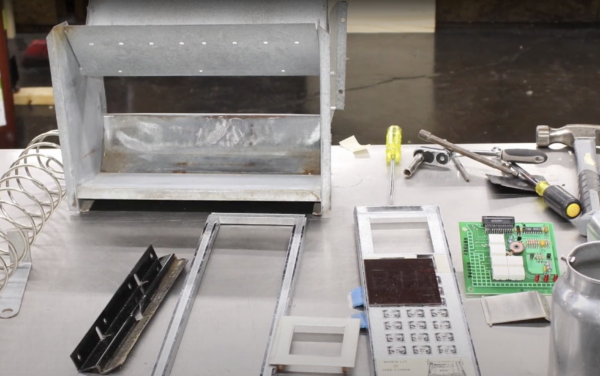

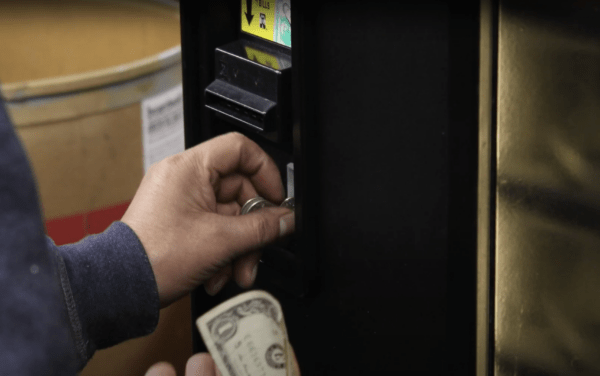

While the vending machine’s cabinet is drying. We clean, inspect, and repair the machine’s working components such as the delivery bins, vend motors, product shelves, coin chutes, cooling systems, and locking mechanisms. Any damaged or failed part is addressed or replaced.

Once the cabinet is dry and the parts inspected and cleaned. The vending machine is moved to assembly. Any pre-ordered customized polycarbonate graphic panels on are in stalled. Polycarbonate panels are easy to clean and resist impacts, dents, and scratches. Providing years of service ability.

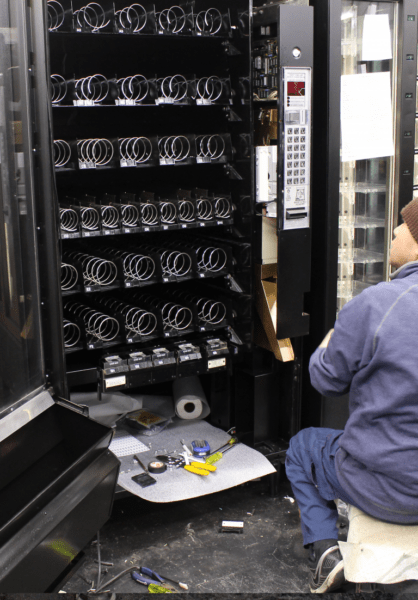

The various parts of the vending machine are now assembled. Care is taken when reinstalling product trays, glass, and all other parts to ensure proper fit. Doors, shelves, and levelers are adjusted for perfect operation.

In the final steps of assembly the vending machine’s electronics are installed. This includes a rebuilt dollar and coin acceptor, main control board, and any other optional accessory. Such as credit card readers and remote sales tracking devices.

Once the vending machine is completely rebuilt. Our factory trained technicians test the vending machine thoroughly. All vending functions are tested such as coin and bill validators and product delivery components. Vend prices are programed according to customers requirements. Drink selection labels are installed in drink vending machine based up customer’s specifications. The machine is now location-ready and moves to shipping.

Since we put tremendous amount of time and effort into our “like new” refurbished vending machine process. We want the machine to arrive at your location in the same condition it left our facility. At no additional cost to you, we package your machine with an eye to proper shipping protection. This includes double metal banded, corner boards, plastic bag, shrink wrap, and leg runners. Places on a 2’x4′ sturdy wooden pallet. At A&M we ship vending equipment all over the world and have negotiated superior shipping rates with many carriers.